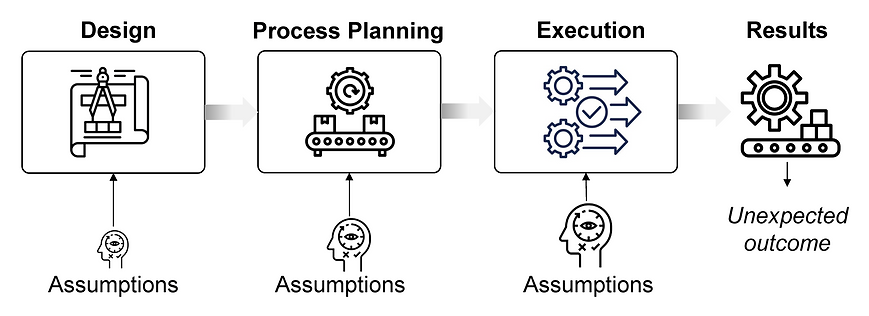

Manufacturing teams make careful decisions at every stage; design, planning, and execution, yet issues still appear late, when changes are costly.

Surprises emerge between disconnected steps; not within them.

OptiScan changes the workflow by introducing one continuous decision flow

OptiScan is integrated manufacturing software that keeps design intent, process logic, and execution context connected, so decisions stay aligned as work moves into production.

OptiScan ensures design, process, and execution stay aligned.

What OptiScan covers

OptiScan supports manufacturing decisions across design, process planning, and execution, so teams can evaluate options early, understand process behavior, and stay aligned as conditions change.

One software system across the full manufacturing decision lifecycle.

When production runs in days, analysis can’t take weeks.

Traditional simulations are built to maximize accuracy once. Design-level decisions are made to explore options quickly.

OptiFab’s design-level thermal simulation is built for the second job, helping teams compare orientations, supports, and layouts early,when decisions are still flexible and time matters most.

Designed to fit how teams work today

OptiScan is delivered with dedicated engineering support, so teams get reliable results without changing tools, workflows, or responsibilities.